So, the reason I'm here. Don't worry, I'll try to keep this as straight-forward and non-technical as possible. However, feel free to follow the links for more detailed information.

I'm working with

Dr. Mary Ellen Zvanut in the Physics department. She specializes in analysis of electronic materials, ones that may be of use sometime in the future. Although she has primarily been working on the potential of using

Silicon Carbide (SiC) for high frequency/high temperature electonics, she has just started working with aother material called

Strontium Titanate (SrTiO3), which is what my project is on.

Strontium Titanate is an interesting material. It was used in the past as a diamond substitute because the way it refracts light is very similar, but it isn't anywhere near as hard. It's also a

superconductor at fairly low temperatures. What Dr. Zvanut is researching is the possibility of usuing this material as a multifunctional material.

What is a multifunctional material? In our computers and electronics today, there are three main kinds of components: electrical (most components), magnetic (hard drives), and optical (lasers, fiber optics). Currently, all these things are separate components that are kind of interconnected. Multifunction materials combine two or more of these properties for new materials that will be able to... Well, I'm not actually sure about that part yet. But something new and revolutionary.

So what is my part in all this? Nothing glorious or mad-scientist-like (no

Frankenstein here...), but it's interesting nonetheless. What I'm using is something called

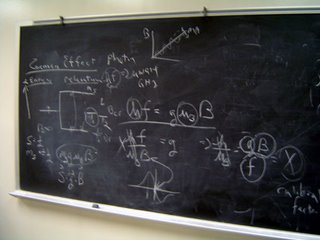

Electon Paramagnetic Resonance (EPR) to analyze small defects in the material. And by small, I mean like a few parts per billion. There are very small impurities of iron and chromium in the material that can make huge differences in the properties of the materials. In adding small amounts of

impurities to silicon is what has allowed virtually every electonic item today to function.

The EPR

The EPR  Me at the EPR computer

Me at the EPR computerThe EPR is basically a pair of really big magnets that can detect these defects. What I do is mount the sample using

rubber cement (hey, but it's

Elmer's rubber cement...), put it in the machine, and run a bunch of scans at different angles and such. Then I anneal the sample (i.e. put it in a furnace) at 400, 570, 750, and 930 degrees F, (man, that would burn the pizza real good), and then do the scans again.

Furnace with vacuum system

Furnace with vacuum systemThe furnace above goes up to 2200 degrees F, and the vacuum system goes to 0.0000002 psi (about 12 billionths of atmospheric pressure).

At this point I'm not really sure what the results will be or what it will mean, but I still have like seven weeks to figure that out, right?

Some other cool stuff:

I jumped off once from where that person's legs are on the above picture. But that was enough. I guess not getting scared/freaking out made the experience less thrilling for me or something. Plus hitting the water hurts.

I jumped off once from where that person's legs are on the above picture. But that was enough. I guess not getting scared/freaking out made the experience less thrilling for me or something. Plus hitting the water hurts.